CRMX-2 Recycle Train Control Computer

Large PLC 12″ Touchscreen CRMX-2 Recycle Train Control Computer

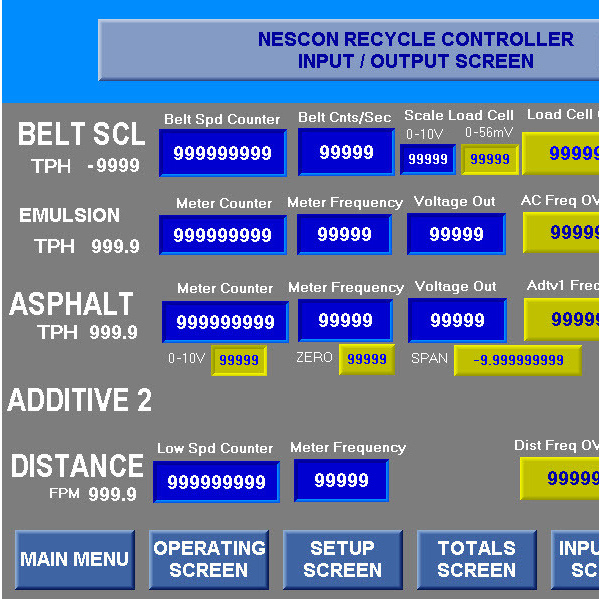

- Belt Scale

- Connects directly to belt scale weigh bridge load cell and belt speed pickup. This eliminates the need for scale integrator.

- Provides for belt speed compensation. Computer will display belt speed in feet (Meters) per minute. Belt speed compensation can be overridden if desired.

- Auto Zero and Auto Span functions.

- Electronic calibration.

- Totalization of RAP material weighed in Tons.

- Display of Load cell voltage values for diagnostics.

- Smoothing coefficient for averaging displayed RAP flow rate.

- Depth sensors can be used with speed sensor in place of scale.

- Asphalt (AC)

- Automatically adjust AC flow rate to achieve desired AC percentage. This can be done by either Increasing and Decreasinga proportional flow valve or by varying an analog voltage output to a motor controller or hydraulic pump.

- Automatically opens and closes a ?SPRAY/RETURN? valve when RAP material starts and stops crossing the belt scale.Allows for AC to circulate to prevent plugging in cold climate conditions.

- Automatic calibration of Asphalt meter.

- Actual weight per gallon of AC can be entered.

- Panel mounted thumbwheel switch for desired AC percentage for easy and quick changes.

- Totalization of AC used in Tons.

- Alarm horn sounds if AC flow rate tolerance exceeded.

- Display of pulses per second from AC meter.

- User can monitor Control output values for diagnostics.

- Adjustable Output control factor to tailor control to different types of pumping equipment.

- Input and Outputs are Optically isolated for protection.

- Verification of spray valve in ?SPRAY? position when mixing.

- Additive (Water)

- Automatically adjust flow rate of water, or any other additive, to desired percentage of RAP.

- Provides output to start and stop a pump or open and close a valve when RAP starts and stops crossing belt scale.

- Automatic Calibration of additive meter.

- Alarm sounds if additive flow rate tolerance exceeded.

- Totalization of additive used in Tons.

- Distance Meter

- Any type of distance pickup can be used.

- System allows for entry of pulses per foot (or Meter) from pickup.

- Display of Feet (or Meters) per minute.

- Totalization of distance (Feet or Meters) processed.

- Beginning Station number can be entered with provisions for counting up or down. This allows for the current station number to print on the production report.

- Allows for entry of Width, Depth, and Density of the uncut asphalt. The computer then can take the current speed and calculate a theoretical Tons per hour being processed. Optionally, this value can be used in place of the Belt scale TPH in the event of a belt scale failure.

- Automatic calibration of distance meter.

- Alarm System

- Allowable tolerance for each product can be entered. If the actual rates are within this tolerance, no alarm will sound.

- Desired time delay before sounding alarm can be entered. This prevents minor fluctuations from creating alarm condition.

- Alarm will sound if Asphalt or Additive spray valves do not index to ?SPRAY? position when needed.

- Printer Option

- Allows for entry of time interval that production values are to be recorded. At each time interval (ie. every 10 minutes), the values for Date, Time, Distance processed (or Station no.), RAP tons, Asphalt tons, and Additive tons are stored in memory.

- The size of the memory allows up to two months worth of data to be stored before being printed.

- Production report can be printed from the stored data.

- Report includes Date, Time, Distance or Station, RAP tons, RAP TPH, Asphalt tons, Asphalt TPH, Asphalt percent of RAP, Additive tons, Additive TPH, and additive percent of RAP.

- All parameter descriptions and values can be printed for a hard copy of calibration data.

- Miscellaneous

- System will work in either English or Metric units.

- Clock/Calender option for report printouts.

- All data and constants maintained in battery backed memory.

- 12 or 24 Volt DC, 110 Volt AC power options.

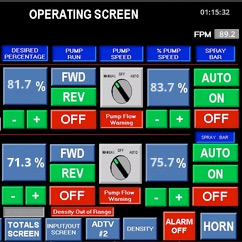

- Complete manual controls for pump flow rates and spray valves.

- Auxiliary meter input with totalizer and rate displays.